The Internet of Things (IoT) is revolutionizing industries across the globe, and supply chain management is no exception. With billions of interconnected devices collecting and analyzing data in real time, businesses can optimize logistics, improve efficiency, and enhance transparency throughout their supply networks. In this article, we will explore the profound impact of IoT on supply chain management and how organizations can leverage this technology to stay ahead in an increasingly competitive market.

The Role of IoT in Supply Chain Management

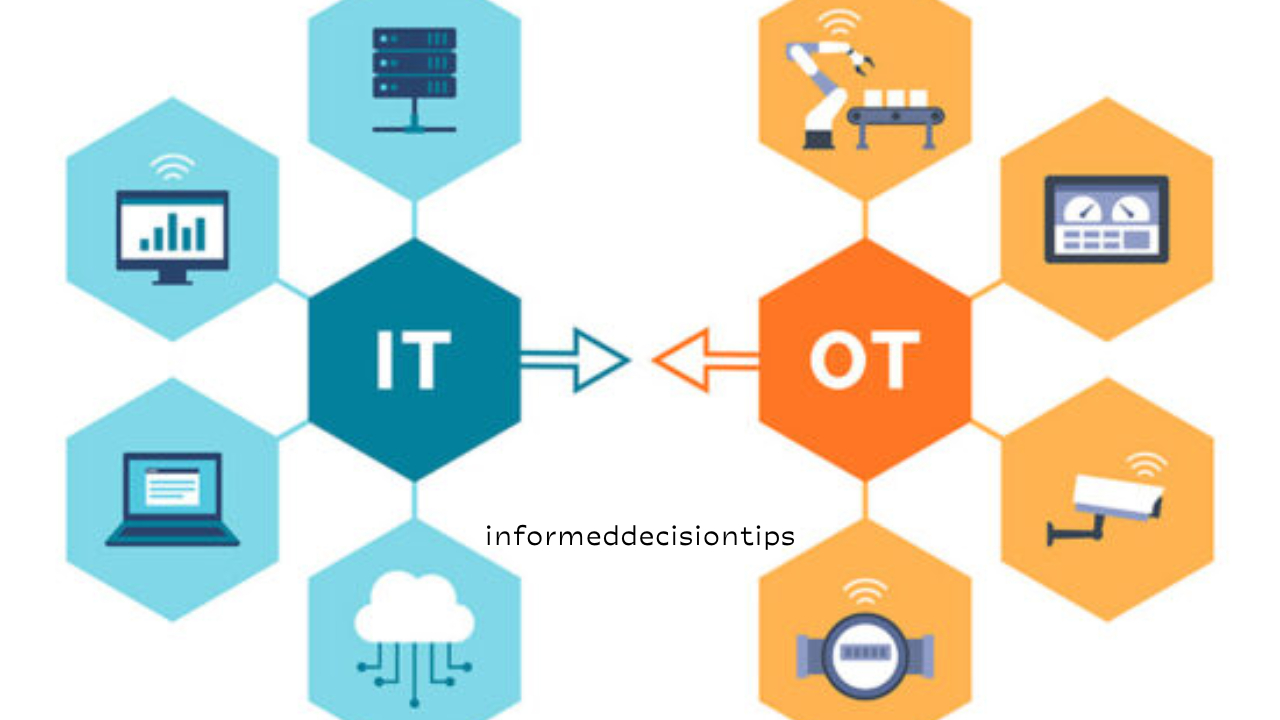

IoT involves embedding sensors, GPS trackers, RFID tags, and smart devices into supply chain operations to enable seamless communication and automation. These technologies provide real-time insights into inventory, shipment status, and overall operational efficiency. Here are some key areas where IoT is making a significant impact:

1. Real-Time Tracking and Visibility

One of the most significant benefits of IoT in supply chain management is enhanced visibility. Companies can track shipments in real time using GPS and RFID technologies, allowing for:

- Accurate ETAs: Businesses and customers receive precise estimated delivery times.

- Loss Prevention: Real-time tracking helps reduce theft and misplaced shipments.

- Route Optimization: Logistics providers can analyze traffic and weather conditions to find the most efficient routes.

2. Smart Warehousing and Inventory Management

IoT is transforming warehouses with automation and intelligent inventory management systems. Some of the most impactful changes include:

- Automated Stock Monitoring: Smart sensors detect stock levels and trigger restocking orders when supplies run low.

- Robotic Automation: IoT-powered robots improve sorting, packing, and warehouse navigation, reducing human error.

- Temperature and Humidity Control: In industries like pharmaceuticals and food logistics, IoT-enabled climate control ensures product safety and compliance.

3. Predictive Maintenance and Equipment Efficiency

IoT devices monitor the health of machinery and transportation fleets in real time. By analyzing sensor data, companies can:

The Role of IoT in Environmental Conservation and Sustainability

- Predict Equipment Failures: Avoid costly breakdowns by addressing potential issues before they escalate.

- Reduce Downtime: Scheduled maintenance can be planned without disrupting operations.

- Improve Fleet Management: Smart sensors in trucks detect fuel consumption, engine conditions, and tire pressure to optimize performance.

4. Enhanced Supply Chain Security

Security is a growing concern in global supply chains. IoT technologies improve security through:

- Smart Locks and Tamper Detection: RFID-enabled locks and motion sensors detect unauthorized access.

- Blockchain Integration: IoT data stored on blockchain ensures transparency and traceability, reducing fraud.

- Geofencing: Alerts are triggered if a shipment deviates from its intended route.

5. Data-Driven Decision Making

IoT generates vast amounts of data that businesses can use to optimize their supply chains. Key applications include:

- Demand Forecasting: Analyzing sales patterns to predict inventory needs and reduce excess stock.

- Supplier Performance Monitoring: Tracking supplier reliability and responsiveness in real time.

- Customer Insights: Understanding purchasing behavior to tailor logistics and delivery strategies.

Case Studies: IoT in Action

1. Amazon’s Smart Warehouses

Amazon has integrated IoT into its warehouses through its robotic fulfillment centers. The use of Kiva robots, RFID sensors, and AI-driven logistics ensures rapid order processing, efficient inventory management, and minimized human intervention.

2. DHL’s IoT-Powered Logistics

DHL has implemented IoT-based solutions such as smart sensors in cargo shipments. These sensors monitor temperature, humidity, and shock levels to ensure sensitive products, such as pharmaceuticals, arrive in optimal condition.

3. Maersk’s Connected Shipping

Shipping giant Maersk leverages IoT-enabled tracking systems to monitor container conditions in transit. This technology provides real-time visibility into temperature-sensitive shipments, improving efficiency in global trade logistics.

Challenges of IoT in Supply Chain Management

While IoT offers numerous benefits, challenges remain in its adoption and implementation:

- High Initial Costs: Investing in IoT infrastructure can be expensive.

- Cybersecurity Risks: IoT networks are vulnerable to cyberattacks and data breaches.

- Integration Complexity: Connecting legacy systems with IoT platforms requires technical expertise.

- Data Overload: Managing and interpreting large volumes of data can be overwhelming without proper analytics tools.

Future of IoT in Supply Chain Management

As technology evolves, IoT is expected to drive further innovation in supply chain management. Future trends include:

- AI and Machine Learning Integration: Smarter analytics for enhanced decision-making.

- 5G Connectivity: Faster and more reliable IoT communications.

- Autonomous Vehicles and Drones: Automated deliveries to improve logistics efficiency.

- Sustainable Supply Chains: IoT-powered monitoring for reduced waste and environmental impact.

How IoT is Improving Agricultural Practices and Food Security

IoT is revolutionizing supply chain management by providing real-time visibility, predictive analytics, and automation. Companies leveraging IoT can improve efficiency, reduce costs, and enhance customer satisfaction. Despite challenges, the future of IoT in supply chains is promising, with continuous advancements paving the way for a more connected and efficient global logistics network. Businesses that embrace IoT will gain a competitive edge, ensuring long-term success in the evolving digital economy.

Leave a Reply